Difference between revisions of "Grid Connection - Wind Energy"

***** (***** | *****) |

***** (***** | *****) |

||

| Line 77: | Line 77: | ||

*Identifying the need of additional reactive compensation devices in the system.<ref>id. p. 12</ref> | *Identifying the need of additional reactive compensation devices in the system.<ref>id. p. 12</ref> | ||

| − | === Reactive Power Control Modes<br> === | + | === Reactive Power Control Modes<br> === |

| − | The least cost effective solution for a wind farm is the operation at constant power factor close to unity of each individual WTG, for which no park-controller is required. This is the classical approach for small wind farms (only a few turbines) connected to distribution grids (<=33kV).<br> | + | The least cost effective solution for a wind farm is the operation at constant power factor close to unity of each individual WTG, for which no park-controller is required. This is the classical approach for small wind farms (only a few turbines) connected to distribution grids (<=33kV).<br> |

| − | In case of wind farms connected to subtransmssion or transmission levels, the system operators usually asks the wind farm operator to maintain a constant power factor, a constant reactive power setting or even the voltage at the grid connection point.<br>Hardware costs of the WTGs depend on the required power factor range (or reactive power range) of each individual WTG. In case of wind farms connected to a transmission or subtransmission level, the power factor range required at the grid connection point is not equal to the power factor range of each WTG because the reactive power need of the step-up transformers and the main grid-transformer has to be covered by the WTGs too. For this reason, there is usually additional shunt capacitors connected near to the grid connection point for complying with reactive power requirements of the system operator.<br>When requiring the operation with unity power factory at the grid connection point, the power factor range of typical WTGs is usually sufficient for covering the reactive power demand of wind farm internal components.<br>When asking for a wider power factor range at the grid connection point, e.g. 0,95, WTGs with wider reactive power range and/or additional shunt capacitors are usually required.<br>Voltage control requires a feed-back loop of the voltage and continuously varying reactive adjustment of the WTGs. Depending on the dynamic requirements (speed of operation) and the required reactive power range of the WTGs, it will be possible to realize voltage control by WTGs and additional shunt capacitors or even additional dynamic reactive power compensation devices, such as SVC or STATCOM might be required, which can have a very high cost impact.<br>Droop control refers to a combined voltage-reactive power control defined by a v-Q characteristic, according to which reactive power is adjusted. Droop control is typically used for fast acting reactive power compensation devices, such as STATCOMs or SVCs.<ref>id. pp.12</ref><br> | + | In case of wind farms connected to subtransmssion or transmission levels, the system operators usually asks the wind farm operator to maintain a constant power factor, a constant reactive power setting or even the voltage at the grid connection point.<br>Hardware costs of the WTGs depend on the required power factor range (or reactive power range) of each individual WTG. In case of wind farms connected to a transmission or subtransmission level, the power factor range required at the grid connection point is not equal to the power factor range of each WTG because the reactive power need of the step-up transformers and the main grid-transformer has to be covered by the WTGs too. For this reason, there is usually additional shunt capacitors connected near to the grid connection point for complying with reactive power requirements of the system operator.<br>When requiring the operation with unity power factory at the grid connection point, the power factor range of typical WTGs is usually sufficient for covering the reactive power demand of wind farm internal components.<br>When asking for a wider power factor range at the grid connection point, e.g. 0,95, WTGs with wider reactive power range and/or additional shunt capacitors are usually required.<br>Voltage control requires a feed-back loop of the voltage and continuously varying reactive adjustment of the WTGs. Depending on the dynamic requirements (speed of operation) and the required reactive power range of the WTGs, it will be possible to realize voltage control by WTGs and additional shunt capacitors or even additional dynamic reactive power compensation devices, such as SVC or STATCOM might be required, which can have a very high cost impact.<br>Droop control refers to a combined voltage-reactive power control defined by a v-Q characteristic, according to which reactive power is adjusted. Droop control is typically used for fast acting reactive power compensation devices, such as STATCOMs or SVCs.<ref>id. pp.12</ref><br> |

| + | |||

| + | <br> | ||

| + | |||

| + | === Impact Studies<br> === | ||

| + | |||

| + | The purpose of system impact studies should be to identify the required reactive power control mode, the required reactive power range and dynamic performance requirements. It is important to consider cost aspects, as described in the previous section for avoiding unnecessary investments.<br>The feasibility of a wind farm consisting of wind generators that operate with constant power factor (at MV-side of WTG step-up transformers) can be evaluated by analyzing P-V-curves for normal operating conditions and for a set of critical contingencies.<br>P-V curves can be used for analyzing voltage variations resulting from:<br> | ||

| + | |||

| + | *Varying wind speed (varying active power generation) | ||

| + | *Contingencies | ||

| + | |||

| + | The P-V curves depicted in Figure 4 apply to normal operating conditions (red curve) and three contingencies (line outages) in the neighborhood of the planned wind farm for the operation with a constant power factor of cos(phi)=1 at the MV-side of each WTG step-up transformer.<br> | ||

| + | |||

| + | <br> | ||

| + | |||

| + | According to the results shown in Figure 4, the maximum voltage at the wind farm connection point would exceed the usual +5% limit and the voltage variation against active power variations would be in the range of approximately 5%. Hence operation with unity power factory would lead to unacceptable voltage variations.<br>It can further be observed from Figure 4 that voltage step changes because of line outages in the neighborhood of the wind farm are within very reasonable limits (around 1%) and don’t cause any problem.<br>The typical approach for mitigating voltage problems, which are due to varying active power levels, is to operate the wind farm with an active power dependent power factor (absorbing vars). This is a very cost effective solution because such a reactive power or power factor characteristic can easily be implemented inside the controller of each individual WTG and doesn’t require any voltage feed-back or global wind farm controller.<br>The resulting PV-curve is depicted in Figure 5. These curves are based on a wind farm with a minimum power factor of 0,95 (absorbing) at the wind farm connection point. The voltage now stays within the required voltage band and voltage variations against active power variations stay within acceptable limits of less than 2%. <ref>id. pp. 13</ref><br> | ||

| + | |||

| + | <br> | ||

| + | |||

| + | [[Image:PV_curves_for_wind-Farm.JPG]]<br> | ||

| + | |||

| + | [[Image:PV_curves_for_wind-Farm_coshi.JPG]]<ref>id. p.14</ref><br> | ||

<br> | <br> | ||

| Line 88: | Line 109: | ||

[[Portal:Wind]] | [[Portal:Wind]] | ||

| + | |||

| + | <br> | ||

<br> | <br> | ||

Revision as of 12:17, 9 July 2011

Grid configuration

For analyzing the grid impact of a wind farm connection at XkV, the following main aspects have to be studied:

• Impact on thermal limits in the surrounding subtransmssion network

• Impact on voltage variations at the connection point and the surrounding subtransmssion system:

• Impact on short circuit levels

• Impact on Power Quality aspects (Harmonics/Flicker, IEC 61400-21)

Each of these aspects requires different types of studies and modelling approaches.[1]

Impact on Thermal Limits in the Surrounding Subtransmission Network

In a first step, it is required to verify that the existing network capacity is able to take the additionally generated power. For this purpose, credible contingencies, such as n-1 branch outages, have to be analyzed.

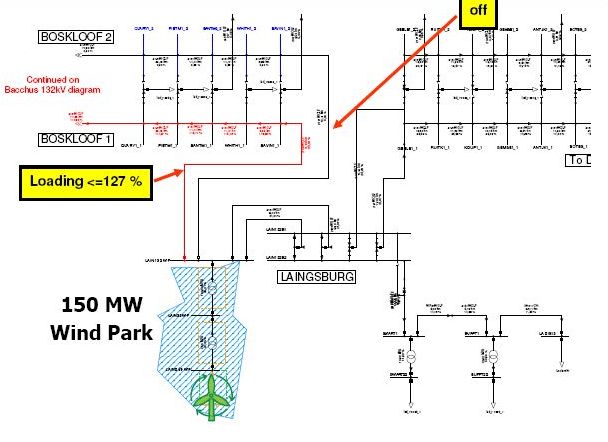

An n-1 analysis based on load flow calculations of all surrounding lines leads to the conclusion that there is a thermal overload problem in the case that one circuit between (in the example that follows) Laingsburg and Boskloof is on outage and the wind farm production is above 120MW. For all other contingencies, no thermal problems can be identified.

The worst case situation with a wind farm production of 150MW and the outage of one of the parallel circuits is depicted in Figure 2. As shown in this diagram, the circuit that will remain in service will carry a load of 127% of its thermal rating.

The general options for mitigating such problems are:

- Reinforce the existing line or build a new line.

- Limit the wind farm during all times.

- Limit wind farm output in case of actual line failure (manual or automatic inter-trip).

- Consider dynamic line rating systems.

Generally, the most economic solution under the constraint that a secure network operation is ensured should be taken. However, the costs associated with each of the four options depend on

- Length of the line

- Number of hours per year during which the overload situation occurs (and during which the wind farm output would have to be limited)

For this reason, only a probabilistic assessment considering the actual wind speed conditions at the site can provide an answer to the question, which mitigation option should finally be applied.

Figure 2: Outage of one of the parallel 132kV lines between Laingsburg and Boskloof[2]

Probabilistic Assessment of the Non Delivered Energy in the Case of Wind Farm Limitation

For analyzing the second mitigation option; that is, limiting the wind farm output to 120 MW during all times (80 % of rated output), the probability that the actually generated power exceeds a level of 80% of installed capacity has to be assessed. For this assessment, the following information is required in addition to a load flow model of the zone of interest:

- Equivalent power curve of the wind farm

- Average wind speed and, if available, the Weibull-shape factor of the wind speed distribution.

In the case that no more detailed information is available, which is usually the case in an early planning stage; a typical power curve of a wind generator can be used as equivalent wind farm power curve. Effects, like wind-farm internal losses etc. can be considered in the equivalent wind farm power curve.

Based on average wind speed and shape factor, the distribution of wind-speeds can be calculated, based on a Weibull distribution. Together with the equivalent wind farm power curve, a wind generation duration curve for one wind farm can be calculated showing the probability for the case that the generated wind power exceeds a given level (see Figure 3).

The energy that cannot be delivered to the system can then be evaluated by calculating the area between that part of the red curve that is above the blue line indicating the wind farm limit and the blue line itself. For a monetary analysis, this area has to be multiplied by the assumed tariff.

The example of Laingsburg (Western Cape, South Africa):

In case of the wind farm at Laingsburg, there were no wind speed data available. For this reason, the corresponding assessment has been carried out for an assumed average wind speed of 7 m/s and 8 m/s. this assessment will provide a good idea about the order of magnitude of the monetary losses associated with a wind farm limitation and at the same time show the sensitivity of this value against average wind speed.

Capping a single wind farm with 7m/s average wind speed at 80% results in a not delivered energy of approximately 5% of the totally available energy. This would be equivalent to around 19 000 MWh/year, which could not be delivered. Assuming a tariff of 1,25 Rand/kWh, the resulting economic losses to the wind farm operators would be in the order of magnitude of 23 750 000 R/year.

If instead 8m/s average wind speed is assumed an considering also an 80% power output limit, the results indicate a not delivered energy of approximately 7,5% of the totally available energy. This would be equivalent to around 37 000 MWh/year, which could not be delivered, resulting in 46 250 000 R/year of losses.[3]

Limit the Wind Farm Output in the Case of an Actual Line Failure

Alternatively, if network operation guidelines allow so, it would be much more economical to limit the wind farm output only under situations, in which one of the circuits between Laingsburg and Boskloof is actually out of service, e.g. because of a planned or an unplanned outage.

In cases, in which there is only a minor overload on the remaining circuit, like in the situation here, it would be possible to limit the wind farm output by a manual post-fault action executed by the network operator.

Alternatively, or in situations in which there is a major overload (above the emergency rating of the line) it is advisable to install an automatic intertrip-schemes that trips some of the wind turbines in the wind farm in the case that the circuit breakers of one of the two parallel circuits are opened.[5]

Dynamic Line Rating Systems

The rating of overhead lines depends on:

- Ambient temperature

- Wind speed and wind direction

In case of cool weather and/or under high wind speeds, overhead lines experience a much better cooling and hence have a much higher rating than under high temperature and/or low wind speed conditions.

Because of the positive correlation between line rating and wind farm output, the installation of a dynamic line rating system at the critical double circuit line can be a very useful option for avoiding grid congestions.

Dynamic line rating systems are either based on:

- Measurement of the conductor temperature

- Measurement of the line sag

- Measurement of ambient conditions

or combinations of some of the above listed measurements. Together with a thermal model of the line, it is possible to predict the actual rating of the line at any moment in time.[6]

Impact on Voltage Variations at the Connection Point and the Surrounding Subtransmission Network

Besides the impact on thermal limits, load flow and contingency analysis studies allow analyzing the impact of wind generation on voltage variations during normal operations and during contingencies.

In a wind generation impact study, the required level of reactive power support of wind farms need to be identified in an early planning stage. Therefore, studies are typically carried out aiming at:

- Identifying the required var-control mode (voltage/droop/const. power factor)

- Identifying the required reactive power range

- Identifying the need of additional reactive compensation devices in the system.[7]

Reactive Power Control Modes

The least cost effective solution for a wind farm is the operation at constant power factor close to unity of each individual WTG, for which no park-controller is required. This is the classical approach for small wind farms (only a few turbines) connected to distribution grids (<=33kV).

In case of wind farms connected to subtransmssion or transmission levels, the system operators usually asks the wind farm operator to maintain a constant power factor, a constant reactive power setting or even the voltage at the grid connection point.

Hardware costs of the WTGs depend on the required power factor range (or reactive power range) of each individual WTG. In case of wind farms connected to a transmission or subtransmission level, the power factor range required at the grid connection point is not equal to the power factor range of each WTG because the reactive power need of the step-up transformers and the main grid-transformer has to be covered by the WTGs too. For this reason, there is usually additional shunt capacitors connected near to the grid connection point for complying with reactive power requirements of the system operator.

When requiring the operation with unity power factory at the grid connection point, the power factor range of typical WTGs is usually sufficient for covering the reactive power demand of wind farm internal components.

When asking for a wider power factor range at the grid connection point, e.g. 0,95, WTGs with wider reactive power range and/or additional shunt capacitors are usually required.

Voltage control requires a feed-back loop of the voltage and continuously varying reactive adjustment of the WTGs. Depending on the dynamic requirements (speed of operation) and the required reactive power range of the WTGs, it will be possible to realize voltage control by WTGs and additional shunt capacitors or even additional dynamic reactive power compensation devices, such as SVC or STATCOM might be required, which can have a very high cost impact.

Droop control refers to a combined voltage-reactive power control defined by a v-Q characteristic, according to which reactive power is adjusted. Droop control is typically used for fast acting reactive power compensation devices, such as STATCOMs or SVCs.[8]

Impact Studies

The purpose of system impact studies should be to identify the required reactive power control mode, the required reactive power range and dynamic performance requirements. It is important to consider cost aspects, as described in the previous section for avoiding unnecessary investments.

The feasibility of a wind farm consisting of wind generators that operate with constant power factor (at MV-side of WTG step-up transformers) can be evaluated by analyzing P-V-curves for normal operating conditions and for a set of critical contingencies.

P-V curves can be used for analyzing voltage variations resulting from:

- Varying wind speed (varying active power generation)

- Contingencies

The P-V curves depicted in Figure 4 apply to normal operating conditions (red curve) and three contingencies (line outages) in the neighborhood of the planned wind farm for the operation with a constant power factor of cos(phi)=1 at the MV-side of each WTG step-up transformer.

According to the results shown in Figure 4, the maximum voltage at the wind farm connection point would exceed the usual +5% limit and the voltage variation against active power variations would be in the range of approximately 5%. Hence operation with unity power factory would lead to unacceptable voltage variations.

It can further be observed from Figure 4 that voltage step changes because of line outages in the neighborhood of the wind farm are within very reasonable limits (around 1%) and don’t cause any problem.

The typical approach for mitigating voltage problems, which are due to varying active power levels, is to operate the wind farm with an active power dependent power factor (absorbing vars). This is a very cost effective solution because such a reactive power or power factor characteristic can easily be implemented inside the controller of each individual WTG and doesn’t require any voltage feed-back or global wind farm controller.

The resulting PV-curve is depicted in Figure 5. These curves are based on a wind farm with a minimum power factor of 0,95 (absorbing) at the wind farm connection point. The voltage now stays within the required voltage band and voltage variations against active power variations stay within acceptable limits of less than 2%. [9]

- ↑ GTZ 2009: Grid Integration of Wind Energy in the Western Cape. p. 7 http://www.gtz.de/de/dokumente/gtz2009-en-grid-study-western-cape.pdf

- ↑ GTZ 2009: Grid Integration of Wind Energy in the Western Cape. pp.8 http://www.gtz.de/de/dokumente/gtz2009-en-grid-study-western-cape.pdf

- ↑ GTZ 2009: Grid Integration of Wind Energy in the Western Cape, pp.9 http://www.gtz.de/de/dokumente/gtz2009-en-grid-study-western-cape.pdf

- ↑ GTZ 2009: Grid Integration of Wind Energy in the Western Cape. p. 11 http://www.gtz.de/de/dokumente/gtz2009-en-grid-study-western-cape.pdf

- ↑ id.

- ↑ id. pp. 11

- ↑ id. p. 12

- ↑ id. pp.12

- ↑ id. pp. 13

- ↑ id. p.14