BLEENS - Biogas, Liquefied Petroleum Gas, Electricity, Ethanol, Natural Gas, and Solar

Introduction

BLEENS cooking solutions: Biogas, LPG, Electricity, Ethanol, Natural gas, and Solar cookers are cooking solutions that typically deliver high performance in terms of reducing household air pollution—often (although not always) regardless of the type of cookstove used—and are collectively called BLEENS. These cooking solutions are often considered “modern” or “clean” solutions.[1]

This article deals with the potentials and limitations of these different alternative cooking fuel options. A table at the end gives a quick overview. Each technology is presented along the following points:

- Source/production of the fuel

- Fuel availability

- Price range

- Applicability/which cooking needs are covered with it?

- Contribution or conflicts with SDGs

Biogas

Biogas is produced by the anaerobic digestion of organic materials such as manure, sewage sludge, organic waste from households, industry waste, and also energy crops. It is composed mainly of methane (40-70%) and carbon dioxide (30-60%)[2]. However, it also contains small traces of other compounds such as hydrogen sulphide, nitrogen, hydrogen, methylmercaptans and oxygen [3]. The energy content of the biogas is directly proportional to the methane content in the biogas (higher methane content is equivalent to higher energy output) [4]. 1 m3 of purified biogas contains 6.5 KW of energy and is equivalent to the following fuels [2][5][6]:- 1.7 L of bioethanol = 1 m3 of purified biogas

- L of gasoline =1 m3 of purified biogas

- 0,97 m3 of natural gas= 1 m3 of purified biogas

- 1 Kg firewood = 0.25 m³ biogas

- 1 Kg dried cow dung =0.1 m³ biogas

- 1 Kg Charcoal = 0.65 m³ biogas

- 1 L LPG = 1.05 m3 of biogas

- 1 kg LPG = 2.1 m3 of biogas

- 1 L of Kerosene = 1.60 m³ biogas

Biogas can be produced in both large scale digesters as well as in small scale digesters in households. This article focuses only on small scale digesters for household level.

Source / Production of Biogas

Technically, biogas is feasible in all climatic conditions but the cost of biogas production increases with a decrease in temperature, making it economically not viable in cold climate (mean temperature below 15°C). This is because in cold climate, an extra heating system has to be installed. For more information, please see this article. A biogas plant has a lifespan of more than 20 years [5].

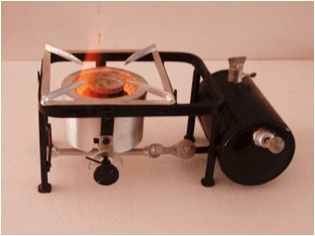

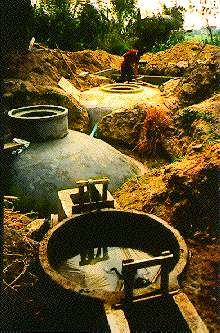

The table below shows the biogas potential of different organic components that are easily available in households. As shown in the figure, cow manure, which is the most common organic compound available in farms has the lowest energy content. Compared to cow manure, other farm outputs such as poultry dropping, grass silage, maize silage have higher biogas yield.

Fuel Availability

As shown in Figure 1, each organic material has different biogas capacity so that determines the quantity required for the biogas production. For an optimal biogas production, it is advisable to mix different available organic components. There is no fixed ratio for mixing but rather depends on the capacity of the digester, the biogas holder, acidity (PH) of the biodigester, carbon-nitrogen ratio of organic substratesetc. See this article for more information.

Assumptions: If a family of 4 members needs 1 m3 of biogas for cooking in a day, then 6 cows with the following factor will yield the required biogas [7][8](Assuming one person requires 0-2 – 0.4 m3 of biogas in a day, only for cooking and then taking the lower value 0.2 m3). This value is based on many assumptions: by simply changing the cow dung output or the retention time in the digester,

the biogas production can be increased or decreased. The biogas feasibility at any farm can also be roughly calculated using the table below:

| No of cows | 6 | |

| Temperature | 22 | °C |

| Cow dung | 10 | kg/day |

| Total cow dung | 30 | kg/day |

| Inflow (1:1 mixing with water) | 60 | L |

| 0.06 | m3/day | |

| Retention time | 30 | days |

| Digester volume (Vd) | 1.8 | m3 |

| Yield (Y) | 5.35 | m3 |

| Volatile solids | 1.42 | kg/day |

| Initial concentration of volatile solids (S) per cow | 23.67 | kg/m3 |

| Total VS | 142 | |

| Gas yield | (Y*Vd*S)/1000 | |

| 1.37 | m3/day |

Price Range

For biogas production, the fuel is mostly the organic waste product. So there is no price range for the fuel. However, high investment is needed in the beginning to construct a biogas plant. The investment cost depends on the size of the biogas plant, availability of construction materials, location of construction, labor wages and end-use applications.

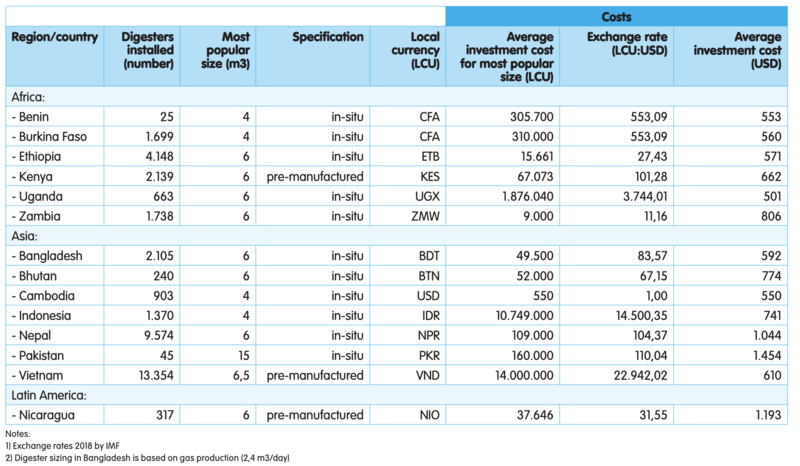

The figure below shows the investment cost for the most popular biodigester size in different countries as calculated by SNV. Click here for more detail on the price calculation. [5].

This figure shows the cost calculation based on data from different sources.Applicability/which cooking needs are covered with it

Biogas can be used for cooking and lighting in households. For cooking, it can be directly used in conventional low-pressure gas burners. It reduces the cooking time as compared to a traditional cookstove [9]. Biogas provides instant heat upon ignition, so no extra waiting time is required. Conventional cooking appliances can also be used by adopting the biogas burners to ensure proper combustion of the energy. It is also possible to regulate the gas flow-rate to regulate the heat from high to low. This allows to cook all kinds of food, those that required high temperature and those that require slow cooking. There are also biogas ovens that can be used for baking.

Since biogas cannot transfer over long distance, they have to be used where they are produced. There are new concepts such as biogas backpack for transporting over distance, but they are not commercially available everywhere.

Contribution or Conflicts with SDGs

Use of biogas replaces the firewood and charcoal for cooking. This reduces the impact on the environment via reduced deforestation. It also reduces the burden on women who initially had to travel far-off distance to collect firewood. There is also no indoor air pollution, which improves the health of the people as compared to cooking with firewood. The cooking pots also do not have soot on them. This makes it easier for the women to wash them [10]. However, biogas can also increase the burden on women as they might be responsible for the biogas. It is physically demanding to move the biogas feedstock, add water to the digestor and also to transport the slurry to the field.

The slurry from biogas production is used as organic fertilizer improving the soil quality and increasing the crop yield. This management of manure also reduces the potential methane emission as major part of the emitting methane is captured in the biodigester. Methane has a heating factor of 21 times of that of CO2. So, burning biogas reduces methane to CO2 and reduces the greenhouse gas impact. A family sized digester can reduce about 2.5 t C02 annually [5]. While construction underground biodigester, special care has to be taken to not to pollute ground water. The slurry has to be also pre-treated before using as fertilizers to kill any harmful pathogens.

Therefore, use of biogas helps to address SDG 3 (eradicate hunger), SDG 7 (renewables) and SDG 13 (climate change). With regard to SDG 5 (gender equality), it could have both positive and negative direct effect, but it depends on what it the overall impact.

►Also see: Environmental Frame Conditions of Biogas Technology

Further Information

- All biogas related information on energypedia

- Cost of biogas plant

- Limitation of Biogas

- Planning guide for biogas plant

- Safety of biogas

References

- ↑ http://documents.worldbank.org/curated/en/650971468180259602/pdf/105054-ESM-P148200-ADD-SERIES-PUBLIC-FINAL-ESMAP-Beyond-Connections-TR008-15-optimized.pdf

- ↑ 2.0 2.1 “Cooking with Biogas - energypedia.info.” [Online]. Available: https://energypedia.info/wiki/Cooking_with_Biogas. [Accessed: 08-Apr-2019]

- ↑ 3.0 3.1 “Biogas Basics - energypedia.info.” [Online]. Available: https://energypedia.info/wiki/Biogas_Basics. [Accessed: 03-Apr-2019].

- ↑ A. Petersson and A. Wellinger, “Biogas upgrading technologies – developments and innovations,” p. 20.

- ↑ 5.0 5.1 5.2 5.3 J. van Hessen, “An Assessment of Small-Scale Biodigester Programmes in the Developing World: The SNV and Hivos Approach,” p. 51.

- ↑ RENA, “Measuring small-scale biogas capacity and production,” /publications/2016/Dec/Measuring-small-scale-biogas-capacity-and-production. [Online]. Available: /publications/2016/Dec/Measuring-small-scale-biogas-capacity-and-production. [Accessed: 08-Apr-2019].

- ↑ IRENA, “Measuring small-scale biogas capacity and production,” /publications/2016/Dec/Measuring-small-scale-biogas-capacity-and-production. [Online]. Available: /publications/2016/Dec/Measuring-small-scale-biogas-capacity-and-production. [Accessed: 08-Apr-2019].

- ↑ “Amount of biogas to cook for a person?” [Online]. Available: https://www.researchgate.net/post/Amount_of_biogas_to_cook_for_a_person. [Accessed: 01-Jul-2019].

- ↑ IRENA, “Biogas for domestic cooking: Technology brief,” p. 32.

- ↑ Global Alliance for Clean Cookstoves, “Biogas.” [Online]. Available: https://www.cleancookingalliance.org/binary-data/TECHNOLOGY_FUELS/document/000/000/6-1.pdf. [Accessed: 08-Apr-2019].

Liquefied Petroleum Gas

Liquefied Petroleum Gas (LPG) is a by-product of extracted natural gas and refined crude oil, with a ratio of 40:60% respectively. It is a mixture of hydrocarbon gases, with the two most common ones being butane and propane[1][2]. It may also contain small amount of propylene and butylene, in addition to traces of ethane, ethylene, pentane and butadiene[3]. This combination of hydrocarbons is vaporous, colorless and odorless at standard room temperature and pressure. With modest pressure and cooler conditions, it can be liquefied and stored in cylinders (cylinders are filled with 80% liquid LPG and 20% gaseous LPG for safety reasons)[3][2]. This liquid is then transported to the end-users in relatively light cylinders. The consumers can convert the stored liquid into usable gas by opening the cylinder’s valve, which decreases the cylinder’s pressure resulting in the vaporization of the stored liquid[3]. LPG claims the leading position among energy carriers, when it comes to energy density, combustion efficiency, heat transfer efficiency and heat control characteristics[2]. LPG has a thermal combustion efficiency of 45% to 60%[4].A typical LPG cooking system is made up of a steel cylinder filled with LPG, a pressure controller, a tube connecting the cylinder to the pressure controller and the burner itself. The burner can consist of one or more cooking tops[5].

The size of the system depends on the size of the cylinder. Cylinders exist in various sizes (2.7 kg, 6 kg, 12 kg, 16 kg). A survey in 20 countries showed that low-income countries households mainly use cylinders smaller than 6 kg. The majority of currently available LPG cylinders are larger (up to 47.5 kg), which proves problematic for low-income households both in the acquisition as well as the recharge of LPG.[5]

►Find more info on advantages and disadvantages of LPG stoves here.

Source / Production of LPG

Generally, LPG either comes directly from gas wells, or as a by-product of the fossil fuels industry, where it is separated from raw oil or raw gas, thus through gas and/or oil extraction, as well as oil and/or gas refinery[1][2]. The global LPG stocks can be divided as: 55%, produced as accompanying products from oil and gas extraction, and 45% as by-products of the refinery processes[1]. LPG is then delivered from supply points in its liquefied form to storage facilities where it is either stored in refrigerated form or in pressurized one[1]. For more information about the production process, read this article on energypedia.

Fuel Availability

LPG exists in abundance and its annual production has been increasing by 3-4% per year worldwide, which led to the consistent excess of LPG’s availability over consumption[4].

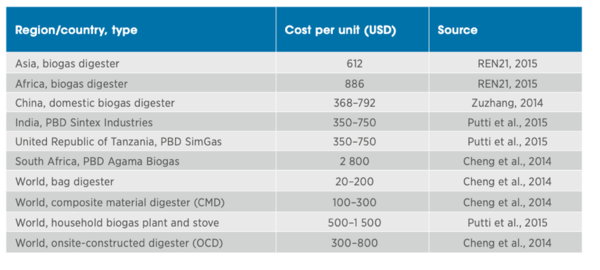

LPG is produced mainly in North-America, the Middle-East and the Asia-Pacific regions, and its production is expected to even expand further[4].

- Access to this clean burning fuel type (LPG) is increasing in the developing world, primarily in urban areas[6]

- In rural areas, LPG supply can be unreliable, if accessible at all[5]

- Less wealthier households tend to use LPG as a minor part of their energy mix especially in situations when smaller food amounts need to be heated fast (e.g. breakfast)[5]

- Important feature of LPG stoves: The stove’s efficiency is about 55-60%, which is much higher than that of many other stoves[7]

Price Range

In urban and peri-urban settings in Sub-Saharan Africa, where cooking fuels are mainly purchased, LPG has proven that it does not cost more than kerosene, wood fuel, biomass pellets and charcoal[4]. However, the upfront cost of LPG equipment and the cost of regular refilling of cylinders could be problematic for low-income households[4].

Since, solid fuels and kerosene can be purchased on a daily basis in a small quantity, while LPG requires a cylinder refill (11-15 kg) every few weeks; LPG could be perceived to be more costly for households. Countries such as Indonesia have also introduced small cylinders to make it less expensive for a refill for poor households[4]. IF LPG is introduced in small cylinders, the overall cost of using LPG will not change but its use may increase as it will be more affordable to poorer households[8].

LPG prices differ from one country/region to another, also from certain time to another even within the same country/region.

This publication states that the prices of 6kg LGP cylinder in Kenya is between 650-1000 KSh and a 13 kg is 1400-2000 KSh[9]. Based on the 2016 report from the GACC, the average cost of LPG for different countries in 2013 is shown below[8].

| China | USD 195.96/year |

| India | USD 84.41/year |

| Bangladesh | USD 489.02/year |

| Guatemala | USD 256.57/year |

| Nigeria | USD 155.87/year |

| Kenya | USD 847.37/year |

| Ghana | USD 193.46 /year |

| Uganda | USD 333.75/year |

According to of LPG 2012-05-08.pdf this presentation from 2012, the average cost of an LPG stove is USD 20-50 and there is a cylinder deposit fee of USD 20-40. The cost of 14.2 kg LPG cylinder in Nepal in 2019 is NPR 1375.[10]

The image also gives a snapshot of residential LPG price in 2012.

- The price of LPG is affected by taxes, subsidies and market distribution costs[5]

- LPG stoves cost around USD 30-100 , which is a barrier for many households[7]

- In Nigeria for example, a competitive kerosene-based cooking system is 83% cheaper[11]

Applicability / which cooking needs are covered with it

LPG consumption is mainly on household level with 49%, followed by its usage in the petrochemical industry with 21.6% and by other industrial uses with 11.8%[1].

LPG is commonly used as cooking fuel by middle to high income households in developing countries[1]. It is used for quick cooking, such as heating water and frying[2]. However, you cannot bake any food using LPG.

LPG stoves are very efficient and are easy to light. They are known to heat quickly, which benefits the users in terms of time saving by faster cooking[4]. For example, in Sri Lanka, due to usage of LPG cookstoves, there was an estimated to be 2-3 hours cooking time saving per day[5][4]. However, LPG have open flames which require airflow to maintain the flames. This airflows also results in heat loss, therefore limiting the effiiciency of cooking. Open fire also includes the danger of fire and burns[9].

The cooks can also easily control the heat with the LPG stoves .

Contribution or Conflicts with SDGs

LPG provides efficient, controllable energy that is easy to transport & store (SDG7)[12].A switch to LPG as a cooking fuel can also result in a significant reduced amount of indoor air pollution[2]. It has the ability to reduce health-adverse exposures by more than 90% compared to traditional stoves, consequently it is directly connected to both SDG3 (good health) and SDG7 (access to energy)[2]. Switching to LPG also impacts the climate (SDG 13), since LPG substantially reduces several pollutants, such as: Sulphur oxide (SOx), nitrous oxide (NOx) and particulate matter. In addition, households, which use charcoal for cooking, produce 5 to 16 times more greenhouse gases per one meal, than those using LPG for the same purpose[2]. Furthermore, less CO2 amounts are emitted when using LPG than those released by burning coal, heating oil or petrol, no black carbon is emitted. LPG is as clean as natural gas, and it releases less pollutants than any other fuel except electricity, thus affecting positively SDG 3 and SDG 13[5][2].

Further Information

- Capstone's Liquefied Petroleum Gas (LPG): Applications and Features (2015)

- Cost-Benefit Analysis of LPG Cookstoves Intervention(2018)

- Kerosene to LP Gas Conversion Programme in Indonesia: A Case Study of Domestic Energy(2015)

- World LPG Association

- The LPG Charte of Benefits (2017)

- Scaling-up Clean Cooking in Urban Kenya with LPG & Bio-Ethanol (2018)

- Scaling-up Demand for LPG in Guatemala: Motivators, Barriers and Opportunities (2017)

- Increasing the Use of Liquefied Petroleum Gas in Cooking in Developing Countries (2017)

- Petroleum Product Pricing, Deregulation and Subsidies in Ghana: Perspectives on Energy Security (2015)

- Cooking with Liquefied Petroleum Gas (LPG)

- LPG Stoves

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 Priesemann, C. & Volkmer, H. (2015). Liquefied Petroleum Gas (LPG). Retrieved from: https://energypedia.info/wiki/Liquefied_Petroleum_Gas_(LPG)

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 Sepp, S. (2014). Multiple Household Fuel Use – A balance choice between firewood, charcoal and LPG. Retrieved from: https://www.cleancookingalliance.org/binary-data/RESOURCE/file/000/000/287-1.pdf

- ↑ 3.0 3.1 3.2 African Oxygen Limited (AFROX). (2018). 2018 Product Reference Manual, Chapter 5: Liquefied Petroleum Gas (LPG). Retrieved from: http://www.afrox.co.za/en/images/2018%20Product%20Reference%20Manual%20full%20version_tcm266-503458.pdf

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 4.6 4.7 Bruce, N.G. Aunan, K. & Rehfuess E.A. (2017). Liquefied Petroleum Gas as a Clean Cooking Fuel for Developing Countries: Implications for Climate, Forests, and Affordability. Retrieved from: https://www.kfw-entwicklungsbank.de/PDF/Download-Center/Materialien/2017_Nr.7_CleanCooking_Lang.pdf

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 https://energypedia.info/wiki/LPG_Stoves

- ↑ https://www.cleancookingalliance.org/technology-and-fuels/stoves/index.html

- ↑ 7.0 7.1 https://energypedia.info/wiki/LPG cooking system

- ↑ 8.0 8.1 Global Alliance for Clean Cookstoves, “Comparative-Analysis-for-Fuels-Appendix-A.pdf,” 2016.

- ↑ 9.0 9.1 https://www.mecs.org.uk/wp-content/uploads/2019/07/The-Kenya-eCookbook-Beans-Cereals-edition-3-July-FULL-RECREATED-WEB-1-4mb.pdf

- ↑ https://kathmandupost.com/columns/2019/09/03/is-electricity-cheap-enough-to-replace-cooking-gas

- ↑ https://energypedia.info/wiki/LPG_Stoves)

- ↑ https://www.wlpga.org/wp-content/uploads/2017/06/The-LPG-Charter-of-Benefits-2017.pdf

Ethanol

Ethanol is an alcohol fuel which can be distilled from a wide variety of biomass feedstock. It is mainly used as transportation fuel, in this case blended with gasoline.For cooking, ethanol and ethanol-based gel-fuel are quite common in niche applications, where clean combustion, safety and convenience are required: e.g. marine markets, camping, catering services and restaurants.

In the development sector its use is mostly restricted to single projects or organizations, recently also under the Clean Development Mechanism[1].

Source / Production of Ethanol

Brazil and the U.S. account for over 80% of global ethanol production today, with Brazil being the world’s biggest ethanol exporter. While in the U.S., ethanol is mainly produced from corn, in Brazil the main raw material is sugar cane[2].

Ethanol (Ethyl Alcohol - C2H5OH) is a clear liquid that can be distilled from starch, which first has to be converted into sugar, or sugar-containing biomass feedstock. Bio-ethanol feedstock can be categorized into three major groups:

- sugar crops (e.g. sugarcane, sugar beet, sweet sorghum and fruits),

- starch crops (e.g., corn, wheat, rice, potatoes, cassava, sweet potatoes and barley), and

- lingo-cellulosic biomass (e.g. wood, straw and grasses

Sugarcane and molasses are the most common and economical sources of ethanol. By using biocatalysts, (micro-organisms including yeast and bacteria), starch or sugar rich plants are fermented to produce ethanol in a relatively dilute aqueous solution (e.g. beer, wine)[3]. Efficient micro-scale distilleries have the capacity to produce from 150 to 5,000 liters ethanol per day[4][1].

Sugarcane production is seasonal, thus ethanol facilities are often inactive for around one third of the year. Alternative feedstocks could increase production and efficiency. For example, sweet sorghum, a cereal, is well suited to the dry, hot conditions present in many developing countries and can also be grown out of the sugarcane season. While the stalks can be used for ethanol production the grain can be used as food. So, there is no competition of using the produce either for food or fuel[5].

Ethanol comes in different levels of purity. The percentage of added water defines its energy content. Technical ethanol with 96% purity is best suited for cooking (Ref).

Besides liquid ethanol, ethanol gel fuel can also be used for cooking. It consists of ethanol and added chemicals, which turn the liquid into a viscous paste. The advantage of this is that if the tank accidentally tips over, the fuel does not spill. However, it does not burn as powerful as liquid Ethanol and can leave a residue when burnt[6].

Fuel Availability

Ethanol has a high energy to volume ratio which makes it ideal for transport. Similarly, storage and transport do not require expensive equipment, unlike LGP for example)[7].

Although ethanol and ethanol based gel fuels can offer a clean and efficient fuel source for households, it might be difficult to set-up a reliable supply chain for ethanol and gel fuel and to encourage rural households, which rely upon cheap or freely gathered fuelwood for cooking to switch to using ethanol as cooking fuel[8].

For urban households already paying for cooking fuel, ethanol could be an alternative to LPG and kerosene - if ethanol is available and prices are comparable. In Kenya, for example, a few providers exist who are at nascent or pilot stage.

Bio-ethanol can be sold in small “refill bundles”, which makes it attractive also for lower-income segments of society.

In Nairobi, locally distributed refilling stations in shops offer a convenient access to fuel for customers. They can not only pre-pay and top up their accounts using mobile money, they also can select the fuel volume to buy[9].

Price Range

Little information is available about prices of ethanol as a cooking fuel. The use of ethanol requires the establishment of a production and supply chain, which very much influences the price of the fuel. In the absence of domestic production, imports are necessary, which make tariff and tax policies a relevant factor of pricing structure. An overview of different tax and tariff burden on imported denatured bio-ethanol in African countries can be accessed in the Kenyan market analysis by Dalberg (p. 29)[9].

In Ethiopia, project Gaia stated in 2013, that ethanol is a cheaper cooking fuel than kerosene and LPG but much more expensive than electricity. They consider, however, its distribution system and the high cost of ethanol stoves as the main barriers in limiting the scale-up of ethanol as a cooking fuel[7].

In 2018, market prices for ethanol in Ethiopia were 17 Ethiopian Birr (ETB), equivalent to 0.5 Euro per liter, whereas kerosene cost 16.4 ETB per liter. Market price for LPG were 30.46 ETB per kg (0,30 Euro) (Ref).

An analysis in 2018 by Dalberg for the Kenyan market showed that liquid bio-ethanol is only available in some areas and is relatively expensive due to tax and tariff treatment compared to other fuels like LPG, kerosene, or charcoal. With a centralized bottle approach, small volumes of Kenyan fuel cost 0.90-1.10 USD/L, and more than USD 1.48 at large scale with imported Bio-ethanol. Ethanol with a “smart fuel ATM approach” cost 0.85 USD/L, sustainable at scale with imported bio-ethanol, including 0.21 USD/L of VAT and import tariffs.

LPG, by comparison, is exempt from both VAT and import tariffs. Ethanol would be the cheapest solution for cooking in Nairobi, if tax and tariff regulations were similar to those of other fuels[9].

Prices of Ethanol stoves range from 15-18 to 45-50 USD for a single burner; retail prices for double burners range from 29-38 to 30-80 USD[10].

In Kenya, a Koko Cooker Kit including a double burner cooker and a canister costs 6,999 KSH, equivalent to EUR 60 (June 2019). This price is subsidized by EcoEye of Korea under the Clean Development Mechanism Carbon project “KOKO Kenya – Ethanol Cookstoves Program”[11] [12].

Applicability/which cooking needs are covered with it

Ethanol burns with a slow, steady and only slightly visible flame. Ethanol should be stored in closed containers and bottles, mainly due to the combustible nature of the ethanol vapour-air mix at certain concentrations, but also due to the possibility of evaporation. Within the household, care must be taken to fully extinguish the flame when filling ethanol stoves, as the flame is very difficult to see.

Among its advantage is that heat is available instantly after ignition. It also provides a safe alternative to LPG when not pressurized.

On the other side, ethanol has a low heating value when further diluted with water to make gel-fuel. And it is highly flammable, burning at low temperatures.

While ethanol burners can be used for boiling, roasting and baking is not possible.

►For more information see also: Cooking with Ethanol

Contribution or Conflicts with SDGs

Since ethanol is a renewable energy source and very clean burning, without smoke, emissions or soot, it contributes positively to SDG 3 (health, well-being), SDG 7 (energy), and SDG 13 (climate change); when ethanol replaces fuelwood it can affect SDG 5 (gender).

If produced domestically and sustainably, ethanol has the chance to also positively contribute to SDG 8 (decent work and economic growth). Furthermore, the development of alternative feedstocks has the potential to improve yields, farmer income and food security (SDG 1 poverty and SDG 2 hunger).

On the opposite side, large scale mono-agricultural production of ethanol can be environmentally damaging, thus affecting negatively SDG 15 (life on land).

Further Information

References

- ↑ 1.0 1.1 https://energypedia.info/wiki/Cooking_with_Ethanol_and_Methanol

- ↑ https://afdc.energy.gov/data/10331

- ↑ https://energypedia.info/wiki/Cooking_with_Ethanol_and_Methanol#cite_note-http:.2F.2Fwww.hedon.info.2FEthanolProduction.3Fbl.3Dy-0

- ↑ https://energypedia.info/wiki/Cooking_with_Ethanol_and_Methanol#cite_note-https:.2F.2Fprojectgaia.com.2Four-approach.2Fthe-fuel.2F-1

- ↑ http://www.hedon.info/EthanolFeedstocks

- ↑ https://www.portablefireplace.com/blog/bioethanol-vs-gel-fuel-comparison/

- ↑ 7.0 7.1 https://projectgaia.com/wp-content/uploads/2013/10/Policy-brief-Finaldocx.pdf Cite error: Invalid

<ref>tag; name "https://projectgaia.com/wp-content/uploads/2013/10/Policy-brief-Finaldocx.pdf" defined multiple times with different content - ↑ Lambe, F. et al (2015) Ethanol: towards a viable alternative for domestic cooking in Ethiopia, Discussion Brief by Stockholm Environmental Institute (SEI) http://cleancookstoves.org/resources/386.html

- ↑ 9.0 9.1 9.2 https://southsouthnorth.org/wp-content/uploads/2018/11/Scaling-up-clean-cooking-in-urban-Kenya-with-LPG-and-Bio-ethanol.pdf

- ↑ http://catalog.cleancookstoves.org/stoves?search=alcohol

- ↑ https://kokofuel.com/terms-conditions/

- ↑ https://kokofuel.com/koko-cooker/

Electricity

In areas which have reliable access to electricity (at least during the cooking time), cooking with electricity can replace other fuel options such as LPG, kerosene etc. Electrical cooking involves either using electrical appliances or using electric stoves. Electric appliances such as electric kettles, rice cookers, ovens and microwaves can be used for specific cooking needs. Electric pressure cookers are another cooking appliance that are highly efficient and are mostly used in Africa, Latin America and Asia to cook grains and other food that need to be cooked for long duration [1]. Electric pressure cooker is a combination of three technologies: electric hotplate, pressure cooker and an insulated hotbox. It is highly efficient as no heat is lost and all the heat goes to the pot[2].Electrical stoves convert electrical energy into heat energy for cooking. There are mainly two types of electric stoves: electrical coil stoves and induction stoves. Electrical coil stoves usually have a lower efficiency and higher power consumption [3][4].

Induction stoves produce heat when a high-frequency magnetic field comes into contact with magnetic cookware such as stainless-steel vessels. They are almost 50% more efficient than electric coil stoves [4]. Electric stoves also have a lifetime of about 10 years[5].

Electric hotplate are the simplest electric cooking devices. The plates heat up when electricity passes through the heating coil. Any kind of pots can be put on the stove to cook.It has a control knob to control the heat [2].

The key variable for cooking with electricity is the unit cost of electricity and the efficiency of the stove (how well it transfers the heat to the pot). In general, cooking with electricity has a thermal efficiency of around 75% [5].

This study analyzed the existing data on cooking to map areas where electric cooking is most viable. The green areas are the ones where it is most viable. This study did not include High Income Countries (HICs). According to the study, electric cooking is most viable in Africa particularly, East and South Africa [6].

The figure below shows the potential for electric cooking in African countries based on different parameters used in the study [6].

The main risk of electric cooking is the burning of think wiring that was installed for lower appliances like lights or phone charging. Thus, before using the electric cooking appliances, is it important to see if the house wiring is suitable to run such appliances[2].

Source / Production of Electricity

The electricity can be generated from different sources such as renewables and fossil fuel. Hence, electrical cooking can be done anywhere where there is access to electricity. Depending on the source of electricity, the impact of electric cooking differs.

Systems such as Solar Home systems and mini-grid can also be used for cooking. However, cooking with SHS and mini-grid increases the peak demand during morning and evening, placing additional demand on the mini-grid. To tackle this problem, use of energy efficient appliances such as electric pressure cookers or load-management (by signaling the users when the supply is limited) is encouraged. Also, this may require an upgraded battery storage system for the mini-grids. Appliances such as hot plate and induction stove are not suitable with SHS as they have high demand spikes. They require large PV and battery system. However, slow cookers and pressure cookers are more suitable for use with SHS as they have low electricity demand profile[1].

Fuel Availability

The adoption of the stoves depends on the availably of electricity and if the voltage is stable. These studies in India and Nigeria show that electrical stoves are mostly used as secondary cooking solutions. Reasons could be low availability of electricity when needed (morning and evenings), fear of high electricity bills and fluctuating voltage (resulting in short circuit connections)[4] [7].

Price Range

Induction stoves can be used at different wattage levels. For example, using an induction stove at 1300 Watt (low voltage) for approx. 2hr a day results in 78 KWh of electricity consumed in a month. The total cost then depends on the electricity tariff in the targeted country and also the price of the stove in the country [4]. On average, this study estimates that annually for a family in Sub-Saharan Africa, it cost USD 200 for operating the stove (maintenance + fuel) and around USD 100 for purchasing the stove [5].

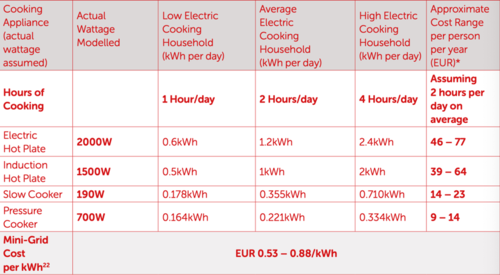

According to this publication, the cost of electric cooking are categorised as below[1]:

|

Appliance |

Cost of the stove (EUR) |

Watts |

Approx. daily household consumption (in MJ) |

|

Single Burner Hot plate |

8-35 |

600-2000 |

4.32-14-40 |

|

Induction hot plate |

45-95 |

1000-2300 |

7.2-16.56 |

|

Electric Pressure Cooker |

19-140 |

500-1000 |

0.58-1.22 |

In key Sub-Saharan African countries such as Tanzania, Kenya, Nigeria and Ghana, the electric cooking appliances are in the range of EUR 12-20 [1].

The figure below shows the cost of SHS required for different types of appliances[1]. It is assumed that after 3 years, the SHS is completely paid and belongs to the user.

The figure below shows the cost of cooking using solar mini-grid[1]: The upfront high cost of electric cooking could be tackled by looking into innovative financing mechanisms such as pay as you go, rent to own model etc. [6].

Applicability/which cooking needs are covered with it

Electric stoves can be used to prepare all kind of meals, except those that require direct contact with flames. For example, Chapatti (flat bread) is a staple food in India but it cannot be cooked on induction stoves [4]. Induction stoves also require the use of stainless-steel utensils with a flat bottom. Any traditional food that requires cooking on mud vessels cannot be used on electric stoves.

Contribution or conflicts with SDGs

Electrical stoves are beneficial to the environment as long as the electricity comes from green sources and not fossil fuel. Electric stoves do not release any kind of smoke and help to avoid indoor air pollution. They also reduce the burden on women as they do not have to travel far off distance to collect firewood. The overall lifecycle impact of electric cooking depends on the source of electricity (how clean it is).

Therefore, a stove operating on clean energy helps to address SDG 4 (health), SDG 5 (gender), SDG 7 (energy), SDG 13 (climate change) and SDG 15 (life on land) if biomass use is reduced.

Further Information

- Publication - Cooking with Electricity: A Cost Perspective

- Presentation: Capturing the Experience of Electric Cooking with Ethno-engineering

- Publication - Electricity as a Cooking Means in Nepal - A Modelling Tool Approach

- Publication - Beyond Fire: How to achieve electric cooking

- Publication - Beyond Fire Back-casting a Pathway to Fully Electric Cooking in Rural Kenya by 2030

- All articles on electricity on energypedia (inlcuding cooking)

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.” Cite error: Invalid

<ref>tag; name "E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.”" defined multiple times with different content Cite error: Invalid<ref>tag; name "E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.”" defined multiple times with different content Cite error: Invalid<ref>tag; name "E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.”" defined multiple times with different content Cite error: Invalid<ref>tag; name "E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.”" defined multiple times with different content Cite error: Invalid<ref>tag; name "E. Matser, H. Clemens, A. Skowron, and J. Thomas, “Beyond Fire: How to achieve electric cooking.”" defined multiple times with different content - ↑ 2.0 2.1 2.2 https://www.mecs.org.uk/wp-content/uploads/2019/07/The-Kenya-eCookbook-Beans-Cereals-edition-3-July-FULL-RECREATED-WEB-1-4mb.pdf

- ↑ “Clean Cooking Alliance,” Clean Cooking Alliance. [Online]. Available: http://cleancookingalliance.org/technology-and-fuels/fuels/. [Accessed: 16-Apr-2019].

- ↑ 4.0 4.1 4.2 4.3 4.4 M. Banerjee, R. Prasad, I. H Rehman, and B. Gill, “Induction stoves as an option for clean cooking in rural India.” 23-Jul-2016.

- ↑ 5.0 5.1 5.2 A. G. Dagnachew, P. L. Lucas, D. P. van Vuuren, and A. F. Hof, “Towards Universal Access To Clean Cooking Solutions In Sub-Saharan Africa,” p. 60.

- ↑ 6.0 6.1 6.2 S. Batchelor, E. Brown, J. Leary, N. Scott, A. Alsop, and M. Leach, “Solar electric cooking in Africa: Where will the transition happen first?,” Energy Research & Social Science, vol. 40, pp. 257–272, Jun. 2018.

- ↑ D. Y. Bisu, A. Kuhe, and H. A. Iortyer, “Urban household cooking energy choice: an example of Bauchi metropolis, Nigeria,” Energy, Sustainability and Society, vol. 6, no. 1, p. 15, Jun. 2016.

Natural Gas

Natural gas (NG) consists of mostly methane (CH4), small amount of natural gas liquids (NGL) and other nonhydrocarbon gases such as carbon dioxide and water vapour. The first usage of NG in America was around 1816, when it was used to illuminate the streets of Baltimore with gas lamps[1]. In the year 1885, Robert Bunsen was able to invent the Bunsen burner that could mix NG with air in the right proportions, creating a flame that could be safely used for heating and cooking[2].

It is colorless, shapeless, and odorless in its pure form[2][1]. NG can be refined and then transported via pipelines or can be liquefied to produce Liquefied Natural Gas for transporting over long distances. NG also has a fuel efficiency of 50-60%, similar to that of LPG [3]. It is mostly used for heating and cooking and is a fossil fuel.

Source / Production of Electricity

The formation of natural gas takes millions of years, as it is formed from the remains of animals and plants, which have died 200-400 million years ago[2][1]. These animals and plants remain built thick layer on the earth’s surface and on ocean floors. Over millions of years, they are covered with layers of sand and silt generating enormous heat and pressure is generated which convert these remains into oil and natural gas. After being formed, natural gas tends to migrate through tiny pores in the surrounding rocks. Some make it all the way to the surface and escape while others migrate until they became trapped under impermeable layers of rock or clay, where they are discovered today as natural gas wells or oil[2][1].

Fuel Availability

There is an abundance in natural gas resources around the world, plus the robust and continuously developing production, makes it a strong competitor among other resources for decades to come[4].

Global proved NG’s reserves have grown approximately 40% along the past two decades, reaching a total of 6950 Trillion Cubic Feet (Tcf) as of January 1st, 2016[4]. Natural gas has basically been discovered in all continents except for Antarctica[2].

East Africa particularly has benefited a lot from natural gas with large discoveries in offshore Mozambique and Tanzania[5]. South Africa also has gas trade with Namibia and Mozambique[20] for natural gas. Nigeria also have huge NG reserves [6].

Price Range

In 2006, the price of liquefied natural gas in China was 5 RMB/m3(€0.43/m3)[7]

Applicability/which cooking needs are covered with it

All kinds of food can be cooked with natural gas except baking. It meets all those cooking needs that LPG meets.

Contribution or conflicts with SDGs

Although natural gas is a fossil fuel, it is considered to be relatively cleaner than coal as it emits 50% less CO2 than coal [8]. Cooking with NG also removes the problem of Indoor air pollution and women also do not have to travel far off to collect fuelwood. This reduces the burden on women and thus contributing positively to SDG 5.

Further Information

- EU's Natural Gas Price Statistics (2019)

- PTT: Natural Gas Information

- Gazprom: The Future Role of Natural Gas (2011)

- IEA's Outlook for Natural Gas (2018)

- QER Appendix B: Natural Gas (2015)

References

- ↑ 1.0 1.1 1.2 1.3 The NEED Project. (2018). Natural Gas. Retrieved from: https://www.need.org/Files/curriculum/infobook/NGasS.pdf

- ↑ 2.0 2.1 2.2 2.3 2.4 Abu-Bakar, W.W. & Ali, R. (2010). Natural Gas. Retrieved from: https://www.researchgate.net/publication/221909211_Natural_Gas

- ↑ A. G. Dagnachew, P. L. Lucas, D. P. van Vuuren, and A. F. Hof, “Towards Universal Access To Clean Cooking Solutions In Sub-Saharan Africa,” p. 60.

- ↑ 4.0 4.1 U.S. Energy Information Administration (EIA). (2016). International Energy Outlook 2016. Chapter 3: Natural Gas. Retrieved from: https://www.eia.gov/outlooks/ieo/pdf/nat_gas.pdf

- ↑ U. Amanam, “Natural Gas in East Africa: Domestic and Regional Use,” 2017.

- ↑ C. Ubani and G. Ani, “Natural Gas Utilization and its Effect on Nigeria’s Economic,” Dec. 2016.

- ↑ “LPG and LNG for Household and Commercial Cooking | ClimateTechWiki.” [Online]. Available: https://www.climatetechwiki.org/technology/lpg_lng_cooking. [Accessed: 05-Aug-2019].

- ↑ “Environmental Impacts of Natural Gas,” Union of Concerned Scientists. [Online]. Available: https://www.ucsusa.org/clean-energy/coal-and-other-fossil-fuels/environmental-impacts-of-natural-gas. [Accessed: 23-Jul-2019].

Solar

Solar energy is the energy, the earth receives from the sun, primarily as visible light and other forms of electromagnetic radiation. Solar thermal energy can be used to heat, cook, bake or pasteurize food or drink.

Fuel Availability

Solar energy is available for free, whenever the sun shines. It can be captured directly with a solar cooker. This also implies that it cannot be used on cloudy, rainy days or at night. Solar cooking thus can never be a stand-alone technology for household use. Solar cookers, however, can complement other stove technologies or back-up by heat retention bags or baskets. They are not emitting any pollutants.

In any case, a detailed assessment of the baseline cooking habits and important factors such as convenience, availability, affordability and reliability are essential to elaborate on the potentials of supplemental solar technologies to an existing household energy mix.

►Readadvantages and disadvantages of solar cookers here.

Types of Solar Cookers and Price Range

The use of solar energy itself is of no cost. However, the cookers need to be purchased. There are different types of solar cookers:

- Parabolic solar cookers

Parabolic solar cookers concentrate the suns’ rays to one focal point that focusses on the bottom of a dark pot or pan. The highly reflective parabolic shape brings the parallel rays of sunlight to a central focal point. Parabolic cookers can be made from aluminium sheets, iron, or even concrete coated with aluminium foil.

Parabolic solar cookers require periodic re-adjustment to track the sun, which can be cumbersome to the cook [1][2].

For more information on parabolic solar cookers read: Cooking with the Sun

Depending of the system costs range usually between Euro 100 and 400 for a household parabolic solarcooker, feeding 5 - 15 people per meal[3].

- Solar box cookers

For more details read also: Solar box cookers

- 'Solar panel cookers'

They mix elements of box and parabolic cookers: a large reflector area and a heat retaining enclosure around the cooking pot. Since they are very easy to construct from low-cost materials they are widely spread, especially in refugee camps[5].

Retail prices of solar panel cookers vary between 3 and 150 USD.

The most widely used solar panel cooker is Solar Cookers International's "CooKit" [5] which is made of cardboard and foil. A heat-resistant plastic bag surrounds the pot and acts like a greenhouse: it allows heat to enter but prevents it from escaping. Manufactured in the USA, it can be fold to the size of a large book for easy transport[6].

Suggested retail prices of the CooKit vary between 3-40 USD[7].

- Scheffler cookers

Example: An Indian temple that is serving up to 50,000 meals per day uses Scheffler reflectors with a steam cooking system. Backed-up with a LPG heating system the cost was nearly $300,000 for the system [10].

More on the technology and its history (in German): http://www.solare-bruecke.org/index.php/de/die-scheffler-reflektoren

Applicability/which cooking needs are covered with it

Parabolic solar cookers

They can reach temperatures of up to 350 °C. These high temperatures enable users to do cooking, stir-frying, grilling, and baking. Since they get very hot, they don’t offer slow-cooking capabilities. Thus, preparing dishes which need longer cooking times at lower temperatures, such as rice and beans, can be difficult. Cooking times on a parabolic cooker are be comparable to an electrical or gas-burning stove[11].

Box cookers

Box cookers are less powerful than parabolic cookers and do not reach temperatures above 200 °C [12]. While they can be used for cooking and baking, stir-frying is not possible, which makes them unsuitable for countries where this type of cooking is common. However, they are easy to handle, orientation to the sun is not as important as for parabolic cookers, and if the sun is temporarily covered by clouds, the temperature does not drop as fast as in parabolic cookers. During cloudy weather, a box cooker can serve as a retained heat cooker[13].

Panel cookers

Panel cookers are capable of cooking up to approximately 140°C (284°F), which means that frying food is not possible. However, they can be used for cooking and baking[5].

Scheffler cookers

They allow all forms of cooking, frying, baking, etc.

Contribution or conflicts with SDGs

In general, solar energy is a renewable energy source available at no cost. It is not emitting any greenhouse gas emissions nor other pollutants; it saves the user money otherwise spent on fuel by replacing biomass or fossil fuels. And it makes energy access possible in areas where biomass is scarce or other fuels are not easily accessible or affordable.

It is thus positively affecting SDG 13 on climate change, SDG 3 on health, SDG 5 on gender, SDG 7 on energy and SDG 15 life on land [14].

However, to which degree solar energy can replace other fuels depends on local dishes and cooking habits. It is also very much dependent on the local climatic conditions, which can vary tremendously over the course of a day or a year. All in all, over the year in a whole, fuel savings amount to roughly 30-40%. (GTZ HERA (2007): Here Comes the Sun. Options for Using Solar Cookers in Developing Countries[15].

Further Information

- GIZ: Solar Cooking Compendium

- All articles on solar cookers on energypedia

- Cooking_with_the_Sun

- All articles related to cooking on energypedia

References

- ↑ https://energypedia.info/wiki/Cooking_with_the_Sun#Parabolic_Solar_Cookers

- ↑ https://www.gosun.co/blogs/news/top-solar-cookers-compared

- ↑ 3.0 3.1 http://catalog.cleancookstoves.org/stoves?search=solar

- ↑ (https://solarcooking.fandom.com/wiki/Category:Solar_box_cooker_designs

- ↑ 5.0 5.1 5.2 https://solarcooking.fandom.com/wiki/Category:Solar_panel_cooker_designs Cite error: Invalid

<ref>tag; name "https://solarcooking.fandom.com/wiki/Category:Solar_panel_cooker_designs" defined multiple times with different content Cite error: Invalid<ref>tag; name "https://solarcooking.fandom.com/wiki/Category:Solar_panel_cooker_designs" defined multiple times with different content - ↑ https://solarcooking.fandom.com/wiki/CooKit

- ↑ http://catalog.cleancookstoves.org/stoves/429

- ↑ https://solarcooking.fandom.com/wiki/Scheffler_Community_Kitchen

- ↑ https://energypedia.info/wiki/Cooking_with_the_Sun#Scheffler_Cookers

- ↑ https://solarcooking.fandom.com/wiki/India#Most_significant_solar_cooking_projects

- ↑ https://solarcooking.fandom.com/wiki/Category:Parabolic_solar_cooker_designs

- ↑ https://solarcooking.fandom.com/wiki/Category:Solar_box_cooker_designs

- ↑ https://energypedia.info/wiki/Cooking_with_the_Sun

- ↑ https://www.un.org/development/desa/disabilities/envision2030.html

- ↑ https://energypedia.info/wiki/File:Using_Solar_Cookers_in_Developing_Countries.pdf

Fuel Comparison

The selection of the appropriate cooking fuel depends on different factors such as: bulk volume (which is important for transport and distribution), calorific values, state of the fuel (solid, liquid and gas) and also procurement cost [1].

In terms of calorific value, wood has a high value such that

| 1 kg of firewood = | 1.5 kg of cowdung |

| 1.2 kg of sawdust | |

| 0.9 kg of charcoal briquettes | |

| 0.7 kg of charcoal | |

| 0.7 kg of ethanol | |

| 0.6 kg of coal | |

| 0.4 kg of kerosene | |

| 0.4 kg of LPG |

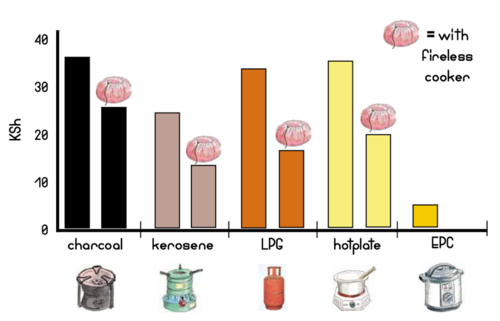

Below is a cost comparison of the different fuels used in Kenya. For this analysis, 500 g of yellow beans was boiled using the different fuels. The beans were either cooked solely using the respective fuel or in combination withfireless cooker*.[2]

- EPC - Electric Pressure Cooker

- Fireless cookers compliment any existing stoves and help to trap the heat. The food is brought to a boil on any other stove and then transferred to the fireless cookers. The cookers are then bundled up tight to avoid any heat escaping. The food will continue to simmer in the cooker, and it will also help to keep the food warm.

References

- ↑ Webinar on Sustainable Energy for Household Cooking Needs in Humanitarian Settings. https://energypedia.info/wiki/Webinar_Series:_Sustainable_Energy_in_Humanitarian_Settings#tab=4th_Webinar

- ↑ The Kenyan eCookbook: https://www.mecs.org.uk/wp-content/uploads/2019/07/The-Kenya-eCookbook-Beans-Cereals-edition-3-July-FULL-RECREATED-WEB-1-4mb.pdf

![Figure 1: Potential of biogas production from different organic materials[6]. It is expressed as m3 of biogas produced per 1t of dry organic mass.](/images/thumb/0/0f/Biogas_production.png/500px-Biogas_production.png)