Cutting 30% of CO2-emissions in constructions - while improving quality and lowering cost

Cutting 30% of CO2-emissions in constructions - while improving quality and lowering cost

Introduction: New Cement Composition developed

The Swiss university École polytechnique fédérale de Lausanne (EPFL) developed the revolutionary cement composition “LC3“ which has the potential to lower global CO2-emissions by 1-2%. The environmental benefits come together with improvements in durability and strength characteristics compared to conventional Portland cement. Very importantly, the innovation is also up to 25% cheaper in production because of energy cost reductions and waste material utilization.[1]

Why are sustainable solutions in cement technology very important for development and climate protection efforts?

With 4’199 million tons of consumption per year, cement is the most produced material in the world and second most consumed item after water. Thereby, the majority of demand comes from fast-growing economies which have high growth rates and strongly invest in construction projects such as China and India. The demand is expected to further increase up to 5’000 million tons per year in 2050. [2]

Considering the availability of resources on earth and the magnitude of worldwide demand for building materials, there is no feasible alternative compared to cement. Moreover, it is also a relatively climate-friendly construction material compared to other materials.

However, the global cement industry is still one of the largest producers of carbon dioxide (CO2) due the large production figures. In total, it accounts for 5% to 10% of worldwide man-made emissions.

Hence, viable solutions for sustainable development efforts need to focus on reducing the emissions of cement utilisation itself. [3]

Potential of LC3- Low Carbon Cement

In cement, the production of clinker is energy- and CO2-intensive. Firstly, clinker needs to be burnt at very high temperatures between 1400 and 1500°C. Secondly, CO2embodied in limestone is released during production. [4]

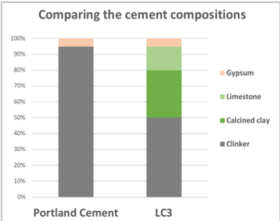

A joint research team from EPFL Switzerland, the Indian Institutes of Technology (IIT) Delhi and Madras, Development Alternatives/TARA and the Cuban institute CIDEM has developed and tested an innovative cement, which is called Limestone Calcined Clay Cement, or LC3for short. This new cement reduces the clinker content to 50% and replaces it with widely available and often waste or second grade materials. These are limestone and clay which can be calcined to activate. [5]

Clays are burned at a lower temperature at around 700 to 800 °C and they do not release embodied CO2. Limestone is used as is without burning. In conclusion, CO2-emissions of the new Limestone Calcined Clay Cement are 30% lower and energy consumption 15 - 20% lower compared to conventional Portland Cement. [6]

LC3is a technically feasible and financially attractive solution

LC3is also very competitive in performance and economic terms. It shows very similar performance characteristics compared to conventional Portland Cement and even outperforms traditional cement in some regards such as resistance to chloride and alkali–silica reaction (called ASR or “concrete cancer”). Apart from the laboratory testing at EPFL and the IITs, several applications have been constructed and they showed very positive results.

Finally, LC3is also up to 25% cheaper in production due to the reduction of the energy-intensive clinker content with widely available and less energy-intensive materials. Investment costs are also low since already existing technologies can be used for the production of LC3. Moreover, this existing economic attractiveness can be further increased by governments through incentives such as tax-reductions in order to accelerate the production of LC3.

Using LC3to achieve Nationally Determined Contributions (Paris Agreement)

LC3can make a difference regarding national CO2-emissions for any country. Especially in developing countries, there is large potential because 80% of cement demand comes from quickly growing economies in Asia, Latin America and Africa.

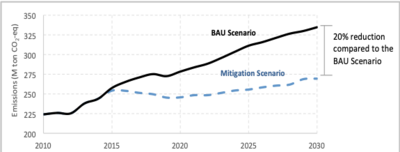

In a first step, calculations were made for several Latin American countries. In its Intended Nationally Determined Contributions (INDCs), Colombia expressed its commitment to reduce its CO2-emissions by 20% until 2030 (see graph).

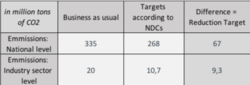

As a result, the NDC- or Mitigation-scenario compared with the Business as usual scenario (BAU) binds Colombia to reduce its national CO2-emissions by 67 million tons until 2030. A share of approximately 9,3 million tons shall be achieved in the industrial field.

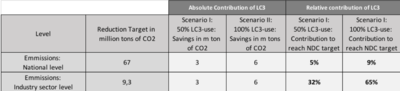

By replacing Portland cement with LC3production, Colombia could easily achieve a large proportion of its climate protection commitment. The higher the percentage of LC3-use, the greater the contribution to the NDC goals.

Even in a conservative scenario of 50% LC3-use by 2030, the Low Carbon Cement could already make a third of the expected savings within the industry sector and 5% for the overall NDC-commitment. With 100% LC3-use this impact could be doubled.

Global impact

On a global level, it is estimated that the utilization of LC3 instead of regular cement can save up to 400 million tons of CO2 per year by 2050. This amount equals France’s entire yearly carbon dioxide emissions or the 1-2% of global CO2-emissions.

When looking at LC3in terms of frameworks such as the United Nations Sustainable Development Goals (SDGs), its potential to contribute to climate action efforts becomes clear. Among other contributions, LC3-Low Carbon Cement can be directly associated with 5 of the 17 Sustainable Development Goals, as shown below:

Conclusion

Climate protection and development efforts often conflict but LC3means that we do not have to choose between these objectives anymore. In fact, LC3is the answer to both of these important goals together. Similar constructions projects can now be realised with a more efficient material which thereby saves 30% of CO2-emissions. Hence, LC3is a solution well-adapted for sustainable development ambitions.[7]