Small-scale Power Generation from Biomass Vol2

Introduction

Biogas technology, the generation of a combustible gas from anaerobic biomass digestion, is a well-known technology. There are already millions of biogas plants in operation throughout the world. Whereas using biogas for direct combustion in household stoves or gas lamps is common, producing electricity from biogas is so far rather rare in most developing countries. In contrast, power generation is the main purpose of biogas plants and a standard technology in Germany and other industrialized countries.

This article is a summary of the documentSmall-scale Electricity Generation from Biomass Part II: Biogas.

The document discusses potentials, obstacles and necessary framework conditions for the utilization of biogas for small and medium scale electricity in developing countries. It is part of a HERA collection of material on small-scale technologies (roughly below 100kW) for power generation from biomass including gasified biomass, biogas, and plant oil. The collection tries to assess the potentials of biomass for the provision of basic electricity services for households, social infrastructure, and small enterprises in areas without connection to a national electricity grid.For comments, questions, and remarks please contact hera@giz.de

The Technology

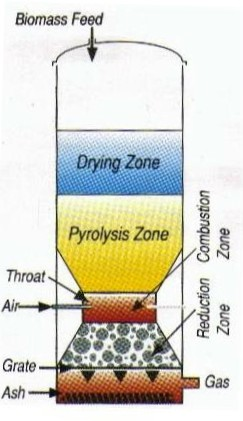

Biogas is the gas resulting from anaerobic digestion process. There are several different gasification methods in use or in development. For the small-scale power gasifiers, the downdraft fixed-bed technology is almost used exclusively. The general process is illustrated in the following table.

| General Down Draft Gasification Process for Small scale gasifiers | |

|

The gasifier is a chemical reactor, where biomas is partially combusted. The gasification process can be distinguished between dehydration (drying of the fuel), Pyrolysis (thermochemical decomposition of organic material), combustion (burning), gasification and reduction of the feedstock.

| |

Projects and Experience in Different Countries

Gasification of biomass or coal is a relatively old technology. Town gas in Western European cities was produced by the gasification of coal before natural gas became widely available. By 1850, large parts of London had gas lights powered by the gas produced from gasifiers using coal and biomass. With the increasing availability of other energy sources and electrification the technology lost its importance. In the early years of the 20th century, gasifier systems to power stationary engines and trucks were demonstrated but did not gain general acceptance. The technology reappeared only after petroleum fuels became scarce during World War II. Almost one million gasifier-powered vehicles were in use during that time. However, with increasing availability of diesel and gasoline this rather inconvenient technology was again abandoned. The energy crisis of the 1970s and 1980s again triggered interest in gasification technology. By the 1980s about 15 manufacturers were offering wood and charcoal power gasifiers. Amongst others, DGIS, GTZ, and SIDA began financing and running pilot gasifier power systems in several developing countries. Brazil, China, India, Indonesia, the Philippines and Thailand had gasifier programmes based on locally developed technologies.

Germany

The technology of anaerobic fermentation and electricity generation from the resulting biogas has been well known for a long time; particularly for sanitation purposes such plants have been in operation for many years. However, power generation from biogas using agricultural feedstock became more common just after the introduction of a feed-in tariff. About 0.11 € per kWh (plus some specific bonuses) was the guaranteed base price for plants up to 150 kW (EEG 2009).

In 2009, more than 4,500 biogas power plants were in operation in Germany with more than 1,500 MW installed power capacity. Hence, specific know-how and technological solutions are available at a very high standard.

However, despite the guaranteed feed-in tariff, the profitability of the plants was not always guaranteed. With fluctuating prices for the feedstock, often especially for plants and grains that were particularly produced for power generation, the profitability of the plants was varying from year to year.

The size of the power plants grew rapidly over the years. While the average size of a biogas power plant was 60 kW in 1999, it was 300 kW only 10 years later (2009). The reason was the decreasing specific cost for bigger plants as can be seen in table 1.

|

|

Cost of CHPgas Motor (in €/kWel) |

Cost of biogas plant (in €/kWel) |

|

|

< 120 kWel |

900 |

3.000 – 5.000 |

|

|

120 – 350 kWel |

740 |

2.000 – 3.000 |

|

|

>350 kWel |

560 |

2.000 |

|

Table 1: Specific investment costs of biogas plants in Germany (2008), based on FNR, 2009

Today, the profitability of biogas plants in Germany depends a lot on the possibility to additionally sell heat beside producing electricity. The heat output of the combined heat and power (CHP) generator is used to provide hot water for community heating systems for households, schools, public swimming pools etc. Furthermore, special bonuses such as bonuses paid for the use of renewable raw material (NaWaRo) are also important for profitable operation of the plants.

Developing and Newly Industrialized Countries

The following chapter will focus on activities carried out in co-operation or at least in close contact with GTZ. Since the late seventies, GTZ has launched several projects for the dissemination of biogas technology. Most of the plants installed by these programmes were designed for households, hospitals and farmers. The main purpose was the direct use of biogas as fuel for cooking and lighting. Sanitation was the main focus of bigger plants constructed for slaughter houses or similar applications.

| Continent | Country | Biogas Programmes and Projects | |

| Africa | |||

| Tanzania | |||

| Asia | Bangladesh | ||

| China | |||

| India |

| ||

| South America | Brazil | ||

Overall Appraisal

Even though availability of operation data is limited, the multitude of gasification projects allows for an appraisal of the following potentials and challenges:

- Energy production potential: Small and medium-size biogas plants could provide a considerable contribution to national electricity generation in many countries. The efficient method to produce electricity from a renewable energy source is possible if the emerging heat from the power generator can be used in an economically and ecologically sound way. The average calorific value of biogas is about 21-23.5 MJ/m³. That means that 1 m³ of biogas corresponds to 0.5-0.6 l diesel fuel or an energy content of about 6 kWh. However, due to conversion losses 1m³ of biogas can be converted only to about 1,7 kWh.

- Technical aspects show that small-scale power-gasifier technology proved to be unreliable and expensive. The used Otto (gasoline) and diesel engines have to be adapted slightly to this fuel. Efficiencies from 7 to 19 per cent. The internal combustion engines have strict purity requirements regarding the generator gas.

- Economic aspects: Economically, electricity from biogas has to mainly compete with electricity generation from fossil fuels. Supporting factors are rising prices of fossil fuels, low reliability of electricity provision from national grids with persistent risk of power cuts.

- Necessary framework conditions: GIZ through its projects and programmes recommends the establishment of guaranteed feed-in price schemes similar to the one in Germany. Besides prices there are still many other barriers relevant to market penetration and development of the biogas sector. As long as the national framework conditions are not favourable, electricity generation from biogas will remain limited to few pilot applications.

Further Information

- Burkard, Thilo(2009): Project cases of Biogas-plants in Kenya. Presentation forBiogas Delegation Trip, Agritechnica 2009. Clearly presented detailed analysis of technical and economic aspects of 5 biogas power plants in Kenya.

- COPEL DISTRIBUIÇÃO S A: VENCEDORES DA CHAMADA PÚBLICA, 2009, 2.p List of the winners of a tender to sell electricity to the grid in the state of Paraná, Brazil

- ESMAP (2005) Advancing Bioenergy for Sustainable Development - Guideline for Policymakers and Investors. Report 300/05.

- Fachagentur Nachwachsende Rohstoffe e.V. (FNR) (2009): Biogas Basisdaten Deutschland – Stand: Oktober 2008. 7p.Very short but comprehensive overview of biogas situation in Germany

- Grope, Johann (2009): Optimierung eines Biogasanlagenmodells unter Berücksichtigung der spezifischen Rahmenbedingungen Südbrasiliens. Study of DBFZ on behalf of GTZ. 84 p. Describes frame conditions of biogas activities in southern Brazil and actual technology. Develops proposals for optimized biogas technology.

- Franz, Michael (2009): Zielmarktanalyse (ZMA). Der Markt für Biogas in Kenia. Studie des Projektentwicklungsprogramm Ostafrika im Rahmen der Exportinitiative Erneuerbare Energien des BMWi.Description of status of biogas technology in Kenya, available local know-how, market potential as well as legal and economic frame conditions in Kenya.Detailed discussion of a biogas plant at a sisal plantation in Kilifi and lessons learned. https://energypedia.info/wiki/File:GTZ_2009_DE_Zielmarkanalyse_Biogas_Kenya.pdf

- Franz, Michael and Klaus v. Mitzlaff (2009): The Biogas Market in Kenya - Status Quo and Potentials. Presentation for Combined Biogas Business and Study Trip from Kenya and Tanzania, to Hannover, November 13, 2009. German Technical Cooperation (GTZ), https://energypedia.info/wiki/File:Gtz2009-en-franz-biogas-status-kenya.pdf

- GTZ (2010): Agro-Industrial Biogas in Kenya – Potentials, Estimates for Tariffs, Policy and Business Recommendations. Study of Deutsches Biomasse Forschungs Zentrum (DBFZ) on behalf of GTZ, Renewable Energy Project Development Programme East Africa. 69p. The comprehensive study documents a high potential for electricity production in Kenya from municipal solid waste and agro-industrial production, especially sisal and coffee production. About 16% of the actual electricity consumption could be covered by electricity from biogas. The costs of different plant types and sizes are calculated. Grid connection and appropriate feed-in-tariffs are identified as main prerequisites for commercial investment in this sector. The proposed basic feed-in-tariffs are in a similar price range as they are actually in Germany (0,10 – 0,2 US$ /kWh el.) http://star-www.giz.de/starweb/giz/pub/servlet.starweb

- GTZ-PURE (2005): Feasibility Study on Biogas from Poultry Droppings in Bangladesh, Prepared By Bangladesh Centre for Advanced Studies (BCAS) in collaboration with Energy Consulting Services (ECS), December 28, 2005. Gives survey of biogas activities in Bangladesh and discusses briefly the possibilities and profitability of electricity generation in Bangladesh. http://www.reein.org/database/gtz/biogas_poultry_drop.htm

- Mitzlaff, Klaus von (1988): Engines for Biogas. GTZ-GATE /Viehweg. 164p. Describes essential basics of internal combustion engines and properties of biogas as a fuel for internal combustion engines. Gives parameters for planning a biogas –engine-system, overview of commercially available systems.

- Muchel, H. u.H. Zimmermann (1985): Purification of Biogas. GTZ: Aus der Arbeit von GATE, 33p. Viehweg. Documents early approaches of GTZ towards electricity generation from biogas. Describes properties and origins of hydrogen sulphide in biogas plants, its effects on the gas-utilization equipment and methods for removing H2S from biogas Available at various websites (not at GTZ), example: of Biogas 1985 B.pdf http://www.cd3wd.com/cd3wd_40/JF/JF_OTHER/SMALL/GTZ-Purification of Biogas 1985 B.pdf

- Practical Action (2009): Small-Scale Bioenergy Initiatives: Brief description and preliminary lessons on livelihood impacts from case studies in Asia, Latin America and Africa. Final report, prepared for PISCES and FAO by Practical Action Consulting. Jan. 2009. 135p.

- Raninger, Bernhard (2009): Biomass-Waste Management - a contribution to a Low CO2-Circular Economy and an Environmental Sound Urban & Rural Development. Presentation for International Symposium on ‘City Group Development Model’, Changsha, Hunan, China, Dec. 3 to Dec. 4, 2009. Bernhard.Raninger@gtz.de. Institute of Clean Energy and Environmental Engineering (ICEEE) and Liaoning Key Laboratory of Clean Energy & Environmental Engineering (LNKLCE) –China & Mining University Leoben, Austria.

- Tomowsky, Arno (2006): GTZ Biogas-experience in Africa. Presentation held at international Workshop on the biogas @Sanitation Initiative for Africa”. Amsterdam, Oct. 2006. A brief summary of GTZ’s lessons learned during more than 20 years of biogas activities in Africa.

References